About the Project

SEAMATICS is an Engineering and Physical Science Research Council (EPSRC) sponsored project for a multi-university research program and a pilot manufacturing facility based at the University of Leeds in the United Kingdom (UK) for developing advanced Photonic Integrated Circuits (PIC). The EPSRC is providing £3.8 million to fund the collaboration under its Manufacturing of Advanced Functional Materials program and Strategic Equipment Grant. The project is also supported by a number of industrial partners.

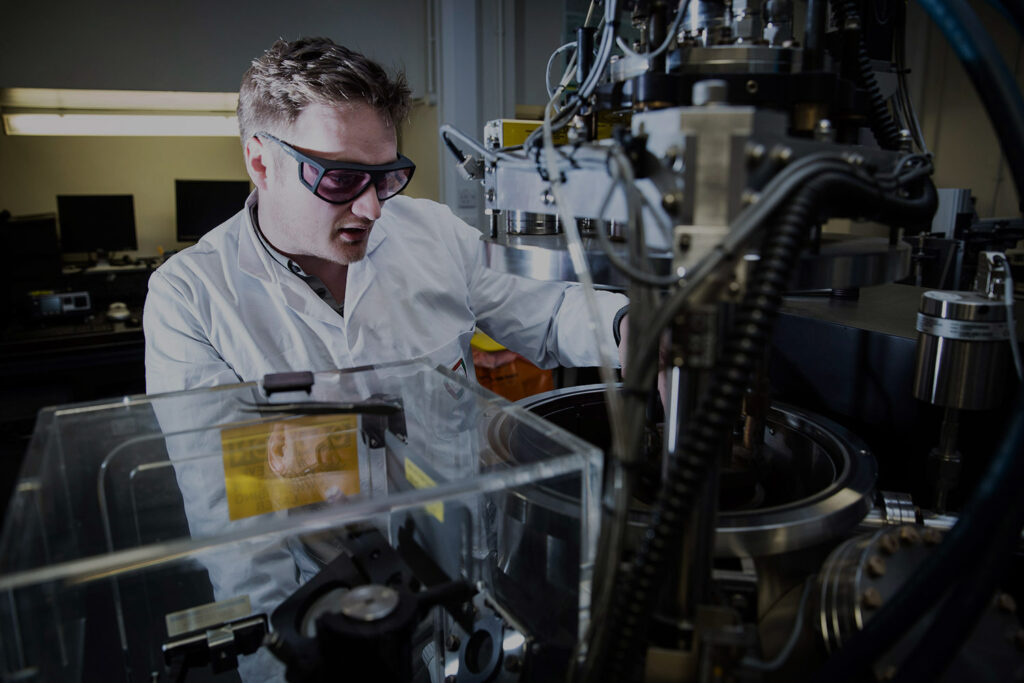

SEAMATICS, led by the University of Leeds , brings together a team of leading UK researchers in photonic materials and devices, from the Universities of Cambridge , York, and Sheffield. The research team from these institutions have expertise in Ultrafast laser plasma process engineering and glass integrated optics, III-V semiconductor materials and devices, polymeric materials and integrated optics, sensor and optical communications sub-systems, and silicon photonics and nanophotonics. Project addresses the lack of a cost-effective and versatile integrated production process and materials platform for the manufacture of PICs. The ultrafast laser plasma implantation (ULPI) manufacturing process uses lasers with pulse durations in the femtosecond range to produce high density and high kinetic energy plasma for optical waveguide fabrication with high concentration rare earth doping. A new manufacturing facility will be setup at Leeds in year 2016 to scale up the process.

The new manufacturing platform offers the on-chip integration of photonic functionalities such as waveguiding, light amplification, lasing, optical switching, and power splitting. In SEAMATICS project, we also aim to combine semiconductor, glass and polymer materials to enable PICs to meet the emerging demands of the optical communications, solid state lighting and microphotonic sensors/imaging device industries.

SEAMATICS platform will eventually lead to a new PIC design, fabrication and device engineering capability with the potential to become a stand-alone financially viable manufacturing centre that will serve the needs of industry and academia.